On 28 March 2025 the government assumed a Caretaker role. Information on websites maintained by the Department of Climate Change, Energy, the Environment and Water will be published in accordance with the Guidance on Caretaker Conventions until after the conclusion of the caretaker period.

Independent Expert Scientific Committee on Unconventional Gas Development and Large Coal Mining Development

Fact sheet - Coal seam gas extraction and co-produced water

What is co-produced water?

Coal seam gas is a natural gas held in coal seams under pressure by groundwater. Coal seam gas wells release the gas by reducing the pressure through groundwater extraction. Extracted water and gas is diverted to surface infrastructure treatment and processing plants (Figure 1). The extracted water is termed ‘co-produced water’ (also referred to as ‘produced water’ or ‘associated water’).

This fact sheet focuses on the management of co-produced water following extraction from the coal seam. It does not consider water management arrangements for aquifer depressurisation resulting from the extraction of co-produced water.

The volume and chemistry of co‑produced water

The volume of co-produced water can vary significantly between individual wells, coal seams and coal basins depending on geological conditions. During the planning phase for gas field development, estimates of co-produced water volumes are necessary to formulate appropriate management arrangements. As the gas field is further developed, more representative data is available on well yield, enabling volumetric predictions to be refined over time. The total volume of co-produced water generated in Australia in 2013 was estimated to be approximately 18 500 megalitres.

Co-produced water is generally brackish, with salinity levels ranging from about 300 to 10 000 milligrams per litre (mg/L). By comparison, the salinity of water supplies for Australian towns can range from less than 250 up to about 1000 mg/L, and seawater is about 35 000 mg/L.

Knowledge of the chemical makeup of co‑produced water is important for its management. This knowledge is used to select appropriate treatment technologies to achieve an acceptable quality for the proposed end use (including discharge).

Uses for co-produced water

Beneficial use or safe discharge of co‑produced water—like any other water use—should be integrated with existing water management arrangements. For example, in Queensland (the major area for coal seam gas development in Australia), management options [5] include irrigation, water for livestock, urban and industrial uses, dust suppression, aquifer reinjection and release to the environment to support local environmental values.

Reinjection of treated or untreated co‑produced water into aquifers can replenish depleted groundwater resources and/or enhance a water resource to support agriculture or groundwater dependent ecosystems. However, successful reinjection relies on a range of factors including suitable hydrogeological conditions, chemical compatibility of receiving groundwater, commercial feasibility and management of well and aquifer clogging.

Co-produced water can substitute for existing rights to water supply from an aquifer or stream, but requires the existing water use developments to be close to the coal seam gas well field.

Water treatment options

Treatment of co-produced water is necessary to provide water managers with options for beneficial use or safe discharge. Treatment reduces salinity and may also be targeted to remove specific contaminants.

Salinity reduction is required for most beneficial uses and for the discharge of co-produced water. Depending upon the volume of water involved, treatment plants may include significant water storage facilities and infrastructure such as the Santos water management facility illustrated in Figure 2.

Reverse osmosis has been widely adopted as a treatment process in Australia and produces both low salinity treated water, and saline ‘brine’. It is primarily a salt removal process and hence organic compounds and some heavy metals may not be removed.

Management of brine

Brine is the highly saline water generated as a residual component of the reverse osmosis process.

Across the coal seam gas production regions, brine is being stored in containment ponds while options for beneficial use and/or disposal are explored. Several options being trialled include commercial salt harvesting and brine reinjection. Other options include ocean outfall or the production of a dry product (zero liquid discharge) for transport or disposal. Further development of feasible brine management options are likely over the next few years.

Discharge to waterways

Where consumptive reuse of co-produced water is not feasible, regulations may allow it be released into waterways or wetlands. For this to occur, the health and biodiversity of aquatic ecosystems must be protected.

Release of co-produced water to natural waterways may cause changes to the flow regime and water quality of receiving waters. Flow impacts may be particularly important for ephemeral streams which do not exhibit perennial flows in their natural state. Important considerations in managing releases of co-produced water therefore include the volume and timing of discharge, and acceptable changes to flow regimes [7].

Water discharged to a stream or wetland would normally be treated to remove salts and other contaminants, and may require post-treatment adjustment. Such adjustments may include re-mineralisation to align the chemistry of discharged waters to that of the receiving waterway or wetland.

Local ecology is likely to have adapted to the natural seasonal flow regime and chemical composition of the stream. Evaluation of ecological risks should therefore consider the implications for in-stream biodiversity and how adverse impacts will be mitigated.

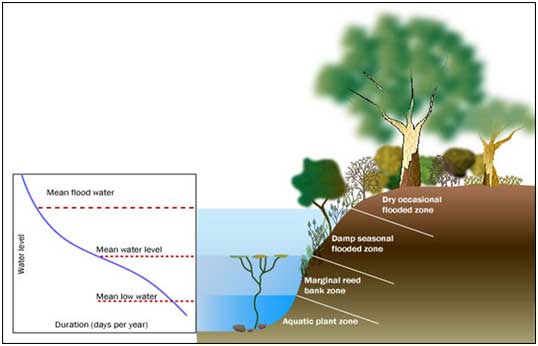

Channel morphology and sediment distribution are also determined by flow regimes. Impacts to riparian vegetation, such as the potential for a change in vegetation zones which could include shifts in community composition or increased colonisation by alien species, also require investigation. Figure 3 illustrates how different riverine vegetation zones depend on different durations of inundation and hence the potential for ecosystem shifts in response to a change in the hydrology of the system. Understanding the vulnerability of such ecosystems to a change in flow regime is therefore an important consideration in determining whether release to the environment is an appropriate management option.

There may be opportunities to enhance ecosystems through well-managed discharge. This applies particularly to inland waterways which, in Australia, are frequently under stress from drought and diversion for consumptive use. However, the long-term dependencies of an ecosystem to supplementary water must be considered. Coal seam gas production fields have a finite life, so it is important to understand the implications from a future reduction in flow after gas production ceases. In other words, it may be necessary to plan for the management of ecosystems stresses as the production of co-produced water declines.

Figure 3: Schematic illustration of the relationship between riverine vegetation zones and varying levels of inundation [8]

Future directions: knowledge gaps and strengthening the science

The coal seam gas industry in Australia is continuing to explore options for the management and disposal of co-produced water and brine. These initiatives are in part a response to regulatory decisions that encourage companies to seek innovative solutions. There is ongoing research on treatment technologies which may be alternatives to, or used in conjunction with, reverse osmosis such as ion-exchange treatment for sodium removal. Some of the innovative management options being explored are outlined in this fact sheet (see Management of Brine). The primary options proposed by the CSG industry are summarised in Table 1.

Characterising the makeup of co-produced water in major coal seam gas producing regions has been a focus of much of the recent research. There are regional and temporal variations in co-produced water chemistry, and there are limited data on the potential occurrence of trace levels of organic compounds.

In regions where there are multiple coal seam gas developments, co-produced water management may require consideration at a catchment scale. For example, critical load thresholds for particular water quality constituents such as salt, nutrients, heavy metals, organic compounds and suspended solids. The lack of available data on these constituents in discharge waters and on the volumes of water that may be discharged has limited the scope of cumulative impact assessments. Improved data availability on co-produced water volumes and chemistry will enable consideration of cumulative impacts at a broader scale.

| Project name | Proponent | Date EIS published | Management options proposed in the EIS |

|---|---|---|---|

| Surat Gas project | Arrow Energy | 2012 | Treated water for agricultural purposes, potable supply or industrial use Disposal of water to watercourses or ocean outfall (less preferred) |

| Australia Pacific Liquefied Natural Gas Project (APLNG Project) | Origin Energy and ConocoPhillips | 2010 | Treated water for agricultural purposes or discharge to a major watercourse |

| Gladstone Liquefied Natural Gas Project (GLNG Project) | Santos and Petronas | 2009 | Dependent on location and water quality:

|

| Queensland Curtis Liquefied Natural Gas Project (QCLNG Project) | QGC | 2009 | Treated water for agricultural purposes, potable supply or industrial/mining use Disposal of water to evaporation ponds (short to medium term solution) Further investigations into forestry, agriculture, reinjection, and industrial and community use underway |

References

[1] CSIRO 2012a, What is coal seam gas, Fact sheet, CSIRO web site, April 2012, accessed 22 July 2014.

[2] APPEA 2014, CSG Industry Data, APPEA website, accessed 22 July 2014.

[3] NHMRC/NRMMC 2011, Australian Drinking Water Guidelines Paper 6 National Water Quality Management Strategy, Commonwealth of Australia, Canberra.

[4] US Geological Survey, The USGS Water Science School, Saline Water, website April 2014, accessed 22 July 2014.

[5] EHP. 2012. Coal Seam Gas Water Management Policy. Brisbane: Department of Environment and Heritage Protection Government.

[6] Photo IESC field trip 2013.

[7] Lovett S. and Price P. (eds) 2007, Principles for riparian lands management, Land & Water Australia, Canberra.

[8] Commonwealth of Australia 2014, Co‑produced Water – Risks to Aquatic Ecosystems, Background Review, Department of the Environment, Canberra.